![]()

|

|

|

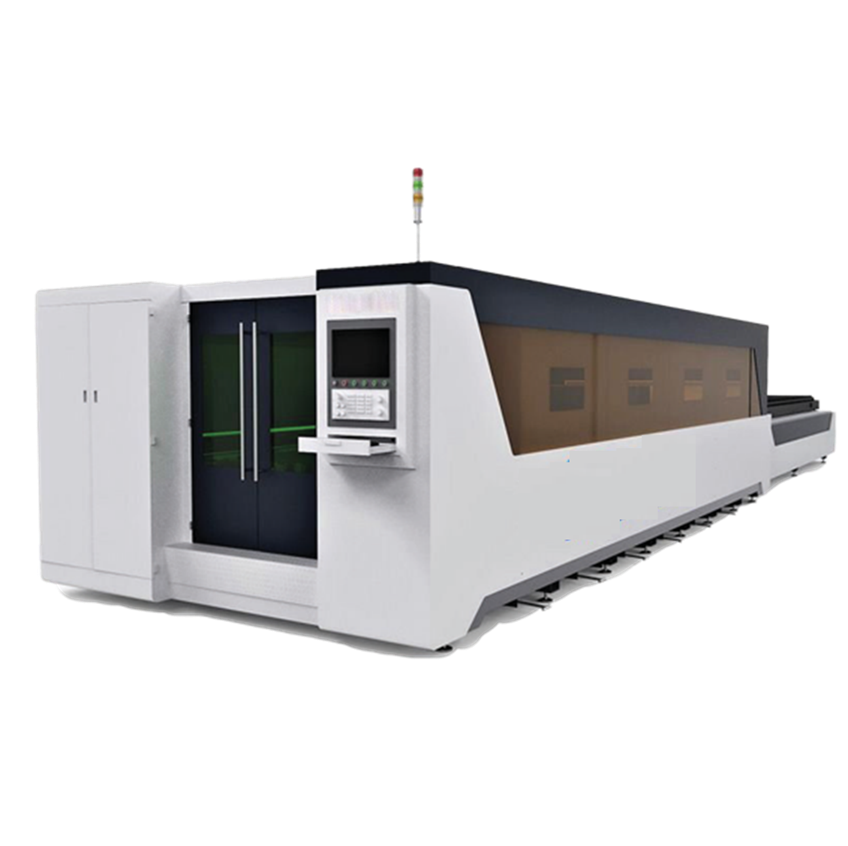

FEATURES • Machine frame is made of

high-strength cast steel intergrally welded structure, heavy weight to help

the vibration stress relief. • Well-knownFIBER LASER source

including Trumpf, IPG, Raycus, Maxphotonics. • Raytools/Precitec Laser Cutting

Head with auto sensor function is suitable for different focal lengths and

controlled by the system. • Japanese Yaskawa AC servo motor and

drive, which is a high accuracy as stable, reliable, good dynamic performance

and strong load capacity. • Auto Oxygen Pressure Regulator

helps to control the flow and ensure the quality of cutting. • Valves are designed to alert the

pressure and airflow, detect failures of oxygen and nitrogen gas

pressure. • X gantry is made by the special

aluminum for laser cutting machines and light weight to support the devices

to move faster but still ensure to be good rigidity. • Smart controller is specially

designed for fiber laser cutting machine and especially, it's

user-friendly. • The cutting parameters are stored

depending on the material thickness. Selecting the available parameters in

the library for using. • The remote penant is one of the

many clever elements that make it easier to control the laser cutting

machine. • Auto lubrication system ensures the

durability and it results in extended equipment life. Selecting the

appropriate lubrication solution can help reduce premature bearing failures

and increase machine uptime, productivity and energy efficiency. • The control cabinet and laser

source are designed to be separat- ed from the body and it's installed in the

cabinet with industrial air-con to create an appropriate working environment

to extend the durability and equipment life. • Exchange of table by lifting tools.

The machine bed is fully covered to ensure the safety issues. • Low operational costs. |

Specifications

|

Product Model |

3015D |

4015D |

4020D |

6015D |

6020D |

6025D |

|

Max cutting size (mm) |

3000x1500 |

4000x1500 |

4000x2000 |

6000x1500 |

6000x2000 |

6000x2500 |

|

Effective travel |

||||||

|

X |

1530 |

1530 |

2030 |

1530 |

2030 6050 170 |

2530 |

|

Axis X (mm) |

||||||

|

Y |

3015 |

4050 |

4050 |

6050 |

6050 |

|

|

Axis Y (mm) |

||||||

|

Z |

170 |

170 |

170 |

170 |

170 |

|

|

Axis Z (mm) |

||||||

|

Positioning Accuracies |

||||||

|

X |

±0.03 |

±0.03 |

±0.03 |

±0.03 |

±0.03 ±0.03 ±0.01 |

±0.03 |

|

Axis X (mm) |

||||||

|

Y |

±0.03 |

±0.03 |

±0.03 |

±0.03 |

±0.03 |

|

|

Axis Y (mm) |

||||||

|

Z |

±0.01 |

±0.01 |

±0.01 |

±0.01 |

±0.01 |

|

|

Axis Z (mm) |

||||||

|

Repeatabilities |

||||||

|

X |

±0.02 |

±0.02 |

±0.02 |

±0.02 |

±0.02 ±0.02 ±0.005 |

±0.02 |

|

Axis X (mm) |

||||||

|

Y |

±0.02 |

±0.02 |

±0.02 |

±0.02 |

±0.02 |

|

|

Axis Y (mm) |

||||||

|

Z |

±0.005 |

±0.005 |

±0.005 |

±0.005 |

±0.005 |

|

|

Axis Z (mm) |

||||||

|

Rapid Positioning Speed |

||||||

|

X |

140 |

140 |

140 |

140 |

140 140 48 |

140 |

|

Axis X (mm) |

||||||

|

Y |

140 |

140 |

140 |

140 |

140 |

|

|

Axis Y (mm) |

||||||

|

Z |

48 |

48 |

48 |

48 |

48 |

|

|

Axis Z (mm) |

||||||

|

Fiber Laser Source |

1500/2000/3000/4000/6000/8000/10000/12000/15000/20000/30000/40000 380V/50Hz and 480/60Hz 3 phase 4.6~60 |

|||||

|

Fiber Laser Power (W) |

||||||

|

Power Requirements |

||||||

|

Power Supply (V) |

||||||

|

Power Consumption |

||||||

|

Power Consumption (kWh) |

||||||

|

Total Weight (Kg) |

6500 |

8000 |

10500 |

11000 |

12000 |

13000 |

|

Machine Dimensions DxRxC Dimension (mm) |

8600x2800 x2100 |

10500x2200 x2100 |

10500x3600 x2100 |

15000x2800 x2100 |

15000x3500 x2100 |

15000x4000 x2100 |